Facilities

Our Manufacturing Process

To provide highest quality and shortest leadtime, we are vertically integrated

Coil Winding

Our coils are enamelled copper wound, well ventilated and insulated by Nomex

Iron Core

We used low loss Grain Oriented Silicon steel and are cut to length via carbide cutting machine to provide max efficiency

Core Stacking

Core are stacked with minimal gaps and checked visually by our engineers.

Varnish Impregnation & Oven Baking

Our transformer go through full varnish dipping process and cured via oven to ensure max bonding and protection against harsh environment

Termination

Copper Busbar or Terminal Blocks are used to allow user to carry proper termination

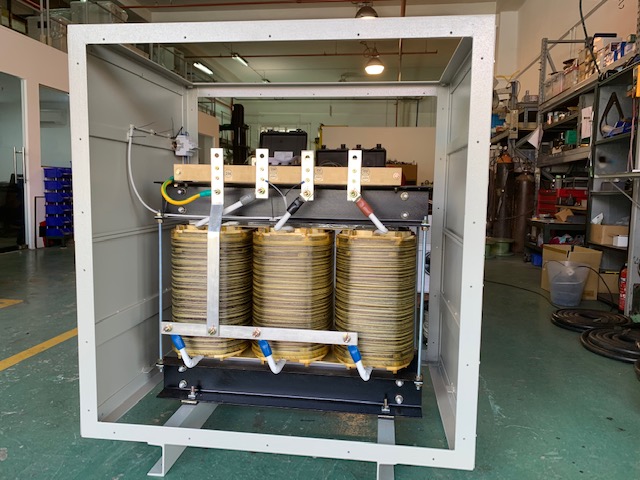

Enclosure Fabrication

Our Enclosure are fabricated in house which also allow our customer to customise to their site conditions

Full Assembly

Transformer & Enclosure are assembled together

Testing

We conduct Routine Test for every transformer before delivery.

Our client also can witness our testing and ensure the transformer meeting to their requirments